Before you start the construction, make sure you know what are the various components and parts reside inside the elegant enclosure of an automatic hand-dryer (H-D). In principle, an automatic H-D consists of the following components and parts.

- Power Supply

- Main Circuit Board (Controller Board)

- Hand-dryer Heater (Heater/Fan Assembly)

- Hand-Proximity Sensor

- Indicators and Switches

Almost all bricks of an automatic H-D can be home-brewed, but a dedicated H-D heater (heater/fan assembly) should be purchased from the external world. Do a little more homework (Google!) before taking your final purchase decision in this regard.

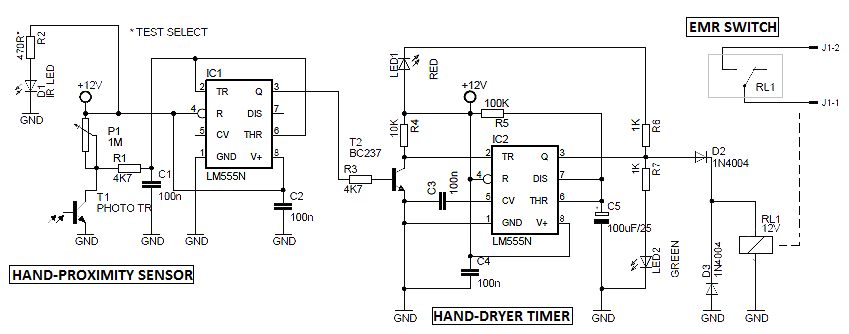

Schematic circuit diagram of our 230V AC operated automatic hand-dryer is shown here. Since the electronic circuitry demands a stable 12V DC supply, make necessary arrangement to provide it from any self-made/ready-made linear or switch-moded power supply unit. The circuit is built around two LM555N chips (IC1&IC2);

IC1 configured as medium-power inverting current driver, and IC2 as monostable multi-vibrator. When infrared light (IR) from the infrared light emitting diode (IR LED) falls on the phototransistor (T1), by reflection, output of IC1 goes to high level and this will switch IC2 through the BC237 transistor (T2). As a result, the electro-magnetic relay – EMR- (RL1) at the output of IC2 is energized to run the hand-dryer heater unit for a prefixed time period determined by the in-circuit values of RC timing components R5 and C5. The red LED (LED1) is the standby mode indicator, and the green LED (LED2) is the active mode indicator. The hand-proximity switching level can be adjusted with the 1M potentiometer (P1). The intensity of the infrared light source depends on the value of current-limiting resistor R2 (tested with 470R).

Both the infrared light source and the phototransistor can be mounted side-by-side on a single panel. But, the infrared light source (IR LED) must be isolated from the phototransistor (T1) (using a small opaque sheet) to avoid false detection due to infrared leakage. The component values are not especially critical. However, the coil of relay RL1 must be have a low operating current, no more than a few dozen milliamperes.

The entire circuit should be fitted in a well-insulated enclosure, since it is usually installed in a watery-area (rest room, bathroom, etc).

No comments:

Post a Comment